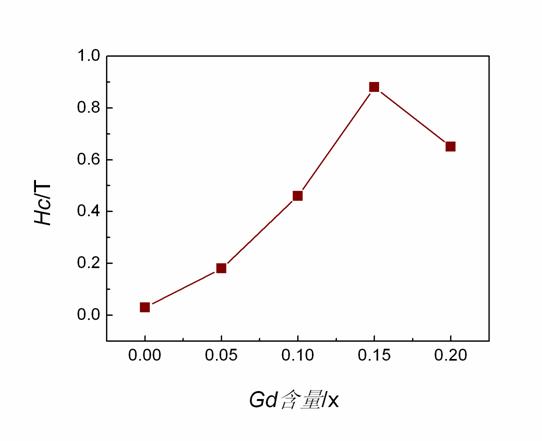

图4 Bi1-xGdxFeO3陶瓷样品的矫顽力随掺杂量变化

图4为室温下Bi1-xGdxFeO3陶瓷矫顽力随掺杂量的变化。由图知,各掺杂样品均出现了较大的矫顽力。由于纯的BiFeO3陶瓷中的矫顽力极小,因此可以认为,大的矫顽力的出现可能是由于稀土离子掺杂所引起的;同时,当稀土离子含量增大时,矫顽力明显增大,也似乎说明矫顽力的主要贡献来自于稀土离子掺杂。而据Cagigas等[11]报道Bi1-xLaxFeO3系列样品也具有较大的矫顽力,但La3+并无磁性,似乎矫顽力的增大与稀土离子本身的磁性无直接关系。因此,我们认为矫顽力增大可能是由于掺杂引起的BiFeO3晶体结构畸变所致。Gd的掺入,导致一定数量的Fe-O-Fe之间的键长和键角发生变化,虽然这些变化引起的各向异性变化不大,但在这个低对称性的体系中很难被忽略,因此对于Bi1-xGdxFeO3陶瓷其大的矫顽力主要由Gd掺杂导致的结构畸变所致。

4 结 论

使用快速升温与退火法制备了Bi1-xGdxFeO3(x=0, 0.05, 0.1, 0.15, 0.2)陶瓷样品,通过XRD图谱发现,掺杂体系在x=0.15附近经历了由三角钙钛矿结构向正交钙钛矿结构的转变,此结构转变在Raman图谱中亦有所反映;通过磁性能测试,发现掺杂大大提高了Bi1-xGdxFeO3陶瓷的铁磁性,这是由于Gd的掺杂影响了BiFeO3陶瓷特有的自旋螺旋反铁磁结构所致;最后,我们认为Bi1-xGdxFeO3陶瓷中大的HC可能是由掺杂引起的结构畸变所致。

[1]S. Bhattacharjee,S. Tripathi and D. Pandey,Appl. Phys. Lett.,91 (2007),042903.

[2]M. M. Kumar,A. Srinivas,et al.,J. Phys: Condens Matters.,11 (1999),8131.

[3]ChaeCheon,JeongSeog Kim and PyungWooJang,J. J. Appl. Phys.,41 (2002),6777.

[4]G. L. Yuan,Siu WingOr andL. W. Chan,J. Phys. D.,40 (2007),1196.

[5]S. Karimi多铁性材料,I. M. Reaney,I. Levin,et al.,Appl.Phys. Lett.,94 (2009),112903.

[6]G. L. Yuan and Siu Wing Ora,J.Appl. Phys.,100 (2006),024109.

[7]Won-Sik Kima,Youn-Ki Juna,Kee Hoon Kimb,et al.,J. Magn. Magn. Mater.,321 (2009),3262.

[8]Manoj Kumar and K L Yadav.,J. Phys.: Condens. Matter.,18 (2006),L503.

[9]J. Wei,R. Haumont,R. Jarrier,et al.,Appl. Phys. Lett.,96 (2010),102509.

[10]V. A. Khomchenko,V. V. Shvartsman,P. Borisov,et al.,Acta. Mater.,57 (2009),5137.

[11]Julian AndresMunevar Cagigas,Dalber Sanchez Candela and Elisa Baggio-Saitovitch,J. Appl. Phys.,200 (2010),012134.

[12] J. B. Li,G. H. Rao andY. Xiao,Acta. Mater.,58 (2010),3701.

[13]PoonamUniyal and K. L. Yadav,Maters.Lett.,62 (2008),2858.

[14]Zhenping Chen,ChunmeiWang and Tao Li,et al.,J. Supercond. Nov. Magn.,23 (2010), 527.

[15]P. Uniyal and K. L. Yadav.,J. Appl. Phys.,105(2009),07D914.

[16]Z. X. Cheng,A. H. Li and X. L. Wang.,et al.,Appl. Phys. Lett.,84 (2004)多铁性材料,1131.

[17] R. Haumont,J. Kreisel,P. Bouvier and F.Hippert,Phys. Rev. B.,73 (2006),132101.

[18]Manoj K. Singh,Hyun M. Jang and Sangwoo Ryu,Appl. Phys. Lett.,88 (2006),042907.

[19]PragyaPandit,S. Satapathy,P. K. Gupta and V. G. Sathe,J. Appl. Phys.,106 (2009),114105.

[20]Nguyen Van Minh,Dao Viet Thang,J. Alloys.Compd.,505 (2010),619.

[21]Shan-Tao Zhang,Ling-Hua Pang and Yi Zhang,et al.,Appl. Phys. Lett.,100 (2006),114108.

[22]G. L. Yuan andSiu Wing Ora,Appl. Phys. Lett.,89 (2006),052905.

Structural and magneticproperties in multiferroic ceramics Bi1-xGdxFeO3 (x=0, 0.05, 0.1, 0.15, 0.2)

Zhou Tong, Shujuan Yuan,Yiming Cao, Hui Xie, Fenfen Chang, Shixun Cao

Physics Department of Shanghai University, Shanghai 200444

Single-phaseBi1-xGdxFeO3 multiferroic ceramics have beensynthesized by the solid state reaction method to study the influence of Gd substitutionon their crystal structure and magnetic behavior. X-ray diffraction and Raman scattering spectra analysis showed that the structure of Gd dopedBiFeO3 was transformed from rhombohedral lattice to orthorhombic by increasingx. Doping with Gd also enhances the ferromagneticmoment, due to the broken cycloid spin structure caused by the distortion inthe crystalline structure. The magnetocrystalline anisotropy contributed by Gddoping gave rise to a large coercivity in Bi1-xGdxFeO3 with an orthorhombicstructure.

Key words: BiFeO3,Multiferroics,Doping

PACC: 7590,7870C,8120L

2/2 首页 上一页 1 2 |